《工业金属管道工程施工规范》GB 50235-2010

VIP免费

3.0

2024-06-16

2

0

754.99KB

108 页

1库币

海报

投诉举报

1

中华人民共和国住房和城乡建设部

中华人民共和国国家质量监督检验检疫总局

___________________________________________________________________________

___________________________________________________________________________

联合发布

UDC

中华人民共和国国家标准

GB

P GB50235—2010

工业金属管道工程施工规范

Code for construction of industrial

metallic piping engineering

2010-08-18 发布 2011-06-01 实施

2

中华人民共和国国家标准

工业金属管道工程施工规范

Code for construction of industrial

metallic piping engineering

GB50235―2010

主编部门:中国工程建设标准化协会化工分会

批准部门:中华人民共和国住房和城乡建设部

施行日期:2011 年 06 月 01 日

中 国 计 划 出 版 社

2010 北京

标准分享网 www.bzfxw.com 免费下载

3

中华人民共和国住房和城乡建设部公告

第 736 号

关于发布国家标准

《工业金属管道工程施工规范》的公告

现批准《工业金属管道工程施工规范》为国家标准,编号为 GB50235-2010,自 2011

年6月1日起实施。其中,第 1.0.5、8.6.1(2)、8.6.6(1)条(款)为强制性条文,

必须严格执行。原《工业金属管道工程施工及验收规范》GB50235-1997 同时废止。

本规范由我部标准定额研究所组织中国计划出版社出版发行。

中华人民共和国住房和城乡建设部

二〇一〇年八月十八日

1

前 言

本规范是根据原建设部《关于印发<二 00 六年工程建设标准规范制订、修订计划

(第二批)>的通知》(建标[2006]136 号)的要求,由中国石油和化工勘察设计协会

和中国化学工程第三建设有限公司会同有关单位在《工业金属管道工程施工及验收规

范》GB50235-1997 的基础上修订完成的。

本规范在修订过程中,规范编制组经广泛的调查研究,认真总结实践经验,参考

有关国际标准和国外先进标准,并在广泛征求意见的基础上,修订本规范,最后经审

查定稿。

本规范共分 10 章和 1 个附录。主要技术内容是:总则,术语和符号,基本规定,

管道元件和材料的检验,管道加工,管道焊接和焊后热处理,管道安装,管道检查、检

验和试验,管道吹扫与清洗,工程交接等。

本规范修订的主要技术内容是:

1 在不适用范围中增加了石油、天然气、地热等勘探和采掘装置的管道,采暖通风

与空气调节的管道及非圆形截面的管道等。

2 增加了“符号”一节。

3 增加了管道分级的规定。

4 增加了管道组成件光谱分析的材质范围。

5 增加了安全阀应进行整定压力调整和密封试验的规定。

6 增补了斜接弯头、焊制翻边接头、支吊架制作的通用技术要求。

7 删除了部分“焊接”的通用技术要求。增补了法兰连接、支管连接的焊接要求。

8 增加了锆材有色金属管道、加套管和阀门安装的通用技术要求。

9 增加了焊缝射线和超声波检测的技术等级要求。

10 增加了“脱脂”一节。

本规范中以黑体字标志的条文为强制性条文,必须严格执行。

本规范由住房和城乡建设部负责管理和对强制性条文的解释,由中国工程建设标

准化协会化工分会负责日常管理,由全国化工施工标准化管理中心站负责具体技术内

容的解释。本规范执行过程中如有意见或建议,请寄送全国化工施工标准化管理中心

站(地址:河北省石家庄市桥东区槐安东路 28 号仁和商务 1-1-1107 室,邮编:050020),

以便今后修订时参考。

标准分享网 www.bzfxw.com 免费下载

2

本规范主编单位、参编单位、主要起草人和主要审查人:

主编单位:中国石油和化工勘察设计协会

中国化学工程第三建设有限公司

参编单位:全国化工施工标准化管理中心站

中国石化集团第五建设公司

中油吉林化建工程股份有限公司

中国二冶集团有限公司管道铁路工程公司

吉林化工学院

山东电力建设第一工程公司

中国机械工业建设工程总公司

中国核工业二三建设有限公司

惠生工程(中国)有限公司

阿美科工程咨询(上海)有限公司

主要起草人:夏节文 张永明 杨 惠 胡忆沩 朱 宇

李功福 张永光 于大江 单承家 赵红梅

芦 天 颜祖清

主要审查人:李柏年 戈兆文 徐明才 谭梦君 李天光 李信浩

王新建 吉章红 王建生 李洪波 武振平 孙 韵

汤志强 张西民 蒋桂英 余月英 陈鸿章

3

目 次

1 总 则···························································································································1

2 术语和符号···················································································································2

2.1 术语························································································································2

2.2 符号························································································································4

3 基本规定·······················································································································6

3.1 一般规定················································································································ 6

3.2 分级························································································································6

4 管道元件和材料的检验·······························································································7

4.1 一般规定················································································································ 7

4.2 阀门检验················································································································ 7

4.3 其他管道元件检验································································································8

5 管道加工·····················································································································10

5.1 一般规定·············································································································· 10

5.2 下料切割·············································································································· 10

5.3 弯管制作·············································································································· 11

5.4 卷管制作·············································································································· 14

5.5 管口翻边·············································································································· 15

5.6 夹套管制作·········································································································· 16

5.7 斜接弯头制作······································································································16

5.8 支、吊架制作······································································································17

6 管道焊接和焊后热处理·····························································································18

7 管道安装·····················································································································23

7.1 一般规定·············································································································· 23

7.2 管段预制·············································································································· 24

7.3 钢制管道安装······································································································24

7.4 连接设备的管道安装··························································································27

标准分享网 www.bzfxw.com 免费下载

4

7.5 铸铁管道安装······································································································28

7.6 不锈钢和有色金属管道安装··············································································29

7.7 伴热管安装·········································································································· 30

7.8 夹套管安装·········································································································· 31

7.9 防腐蚀衬里管道安装··························································································31

7.10 阀门安装············································································································ 31

7.11 补偿装置安装 ···································································································· 32

7.12 支、吊架安装····································································································36

7.13 静电接地安装····································································································38

8 管道检查、检验和试验·····························································································39

8.1 一般规定·············································································································· 39

8.2 外观检查·············································································································· 39

8.3 焊缝表面无损检测······························································································39

8.4 焊缝射线检测和超声检测··················································································39

8.5 硬度检验及其他检验··························································································40

8.6 压力试验·············································································································· 40

9 管道吹扫与清洗·········································································································45

9.1 一般规定·············································································································· 45

9.2 水冲洗··················································································································46

9.3 空气吹扫·············································································································· 46

9.4 蒸汽吹扫·············································································································· 47

9.5 脱脂······················································································································47

9.6 化学清洗·············································································································· 48

9.7 油清洗··················································································································48

10 工程交接···················································································································49

附录A 施工质量检查记录的内容及格式····································································51

本规范用词说明···············································································································68

引用标准名录 ·················································································································69

附:条文说明 ·················································································································70

5

Contents

1 General provisions············································································································1

2 Terms and symbols···········································································································2

2.1 Terms·······················································································································2

2.2 Symbols ···················································································································4

3 Basic Requirement············································································································6

3.1 General Requirement·····························································································6

3.2 Classes ·····················································································································6

4 Inspection of pipework components and materials························································7

4.1 General requirement ······························································································7

4.2 Valve inspection ······································································································7

4.3 Inspection of other pipework components ····························································8

5 Machining of piping ··········································································································10

5.1 General requirement ····························································································10

5.2 Pipe cutting·············································································································10

5.3 Bending fabrication ······························································································11

5.4 Machining of rolling tube·····················································································14

5.5 Flanging edge of pipe····························································································15

5.6 Machining of jacket piping ··················································································16

5.7 Fabrication of miter elbow···················································································16

5.8 Fabrication of piping support and hanger··························································17

6 Welding and heat-treatment after welding of piping ···················································18

7 Installation of piping ····································································································23

7.1 General requirement ····························································································23

7.2 Prefabricating for section of pipe ········································································24

7.3 Steel piping installation ························································································24

7.4 Piping installation of coupling equipment···························································27

标准分享网 www.bzfxw.com 免费下载

6

7.5 Cast iron piping installation·················································································28

7.6 Installation of stainless steel piping and nonferrous piping·····························29

7.7 Heating piping installation···················································································30

7.8 Jacket piping installation ·····················································································31

7.9 Installation of anti-corrosion lining piping ·························································31

7.10 Valve installation·································································································31

7.11 Expansion joint installation················································································32

7.12 Installation of piping support and hanger ·······················································36

7.13 Installation of static electricity grounding ························································38

8 Inspection, examination and test of piping ···································································39

8.1 General requirement ····························································································39

8.2 Visual examination ·······························································································39

8.3 Non-destructive testing of welding seam surface················································39

8.4 Radiographic and ultrasonic examinations of welding seam·····························39

8.5 Hardness examination and other inspections ·························································40

8.6 Pressure test ··········································································································40

9 Blowing and Cleaning of Piping ····················································································45

9.1 General requirement ····························································································45

9.2 Water flushing·······································································································46

9.3 Air blowing············································································································46

9.4 Steam blowing·······································································································47

9.5 Degreasing·············································································································47

9.6 Chemical cleaning·································································································48

9.7 Oil cleaning ···········································································································48

10 Hand-over of Engineering·························································································49

Appendix A Content and form for inspection record of construction quality···············51

Explanation of wording in this code·····················································································68

List of quoted standards········································································································69

Addition: Explanation of provisions··················································································70

1

1 总 则

1.0.1 为提高工业金属管道工程的施工水平,加强工业金属管道工程施工过程的质量控

制,保证施工质量,制定本规范。

1.0.2 本规范适用于设计压力不大于 42MPa,设计温度不超过材料允许使用温度的工业

金属管道工程的施工。

1.0.3 本规范不适用于下列工业金属管道的施工:

1 石油、天然气、地热等勘探和采掘装置的管道;

2 长输管道;

3 核能装置的专用管道;

4 海上设施和矿井的管道;

5 采暖通风与空气调节的管道及非圆形截面的管道。

1.0.4 工业金属管道的施工,应按设计文件及本规范的规定进行。

1.0.5 当需要修改设计文件及材料代用时,应经原设计单位同意,并应出具书面文件。

1.0.6 现场组装的设备所属管道的施工,应按制造厂的产品技术文件进行,且不得低于

本规范的规定。

1.0.7 本规范应与现行国家标准《工业金属管道工程施工质量验收规范》GB50184 配合

使用。

1.0.8 工业金属管道防腐蚀工程的施工,应符合国家现行标准和设计文件的规定。

1.0.9 工业金属管道绝热工程的施工,应符合现行国家标准《工业设备及管道绝热工程

施工规范》GB50126 和设计文件的规定。

1.0.10 工业金属管道的施工,除应符合本规范外,尚应符合国家现行有关标准的规定。

标准分享网 www.bzfxw.com 免费下载

摘要:

展开>>

收起<<

1中华人民共和国住房和城乡建设部中华人民共和国国家质量监督检验检疫总局______________________________________________________________________________________________________________________________________________________联合发布UDC中华人民共和国国家标准GBPGB50235—2010工业金属管道工程施工规范Codeforconstructionofindustrialmetallicpipingengineering2010-08-18发布20...

温馨提示:66文库网--作为在线文档分享平台,一直注重给大家带来优质的阅读体验;让知识分享变得简单、有价值;海量文档供您查阅下载,让您的工作简单、轻松而高效!

1. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

2. 66文库网仅提供信息存储空间,仅对广大用户、作者上传内容的表现方式做保护处理,对上传分享的文档内容本身不做任何修改或编辑,并不对下载的任何内容负责。

3. 广大用户、作者上传的文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

4. 本站不保证、不承担下载资源内容的准确性、安全性和完整性, 同时也不承担用户因使用下载资源对自己和他人造成任何形式的伤害或损失。

相关推荐

-

168种常用化学品MSDSVIP免费

2024-07-28 35

2024-07-28 35 -

2024年安全生产月消防知识竞赛活动策划二(61页)VIP免费

2024-09-13 4

2024-09-13 4 -

21特种作业安全生产基本知识VIP免费

2024-09-15 5

2024-09-15 5 -

2024年春节前安全工作重点暨假期安全提示(60页)VIP免费

2024-09-15 11

2024-09-15 11 -

公共交通线路优化与出行调度方案

2024-09-26 8

2024-09-26 8 -

2024消防安全基础知识培训(55页)VIP免费

2024-09-29 8

2024-09-29 8 -

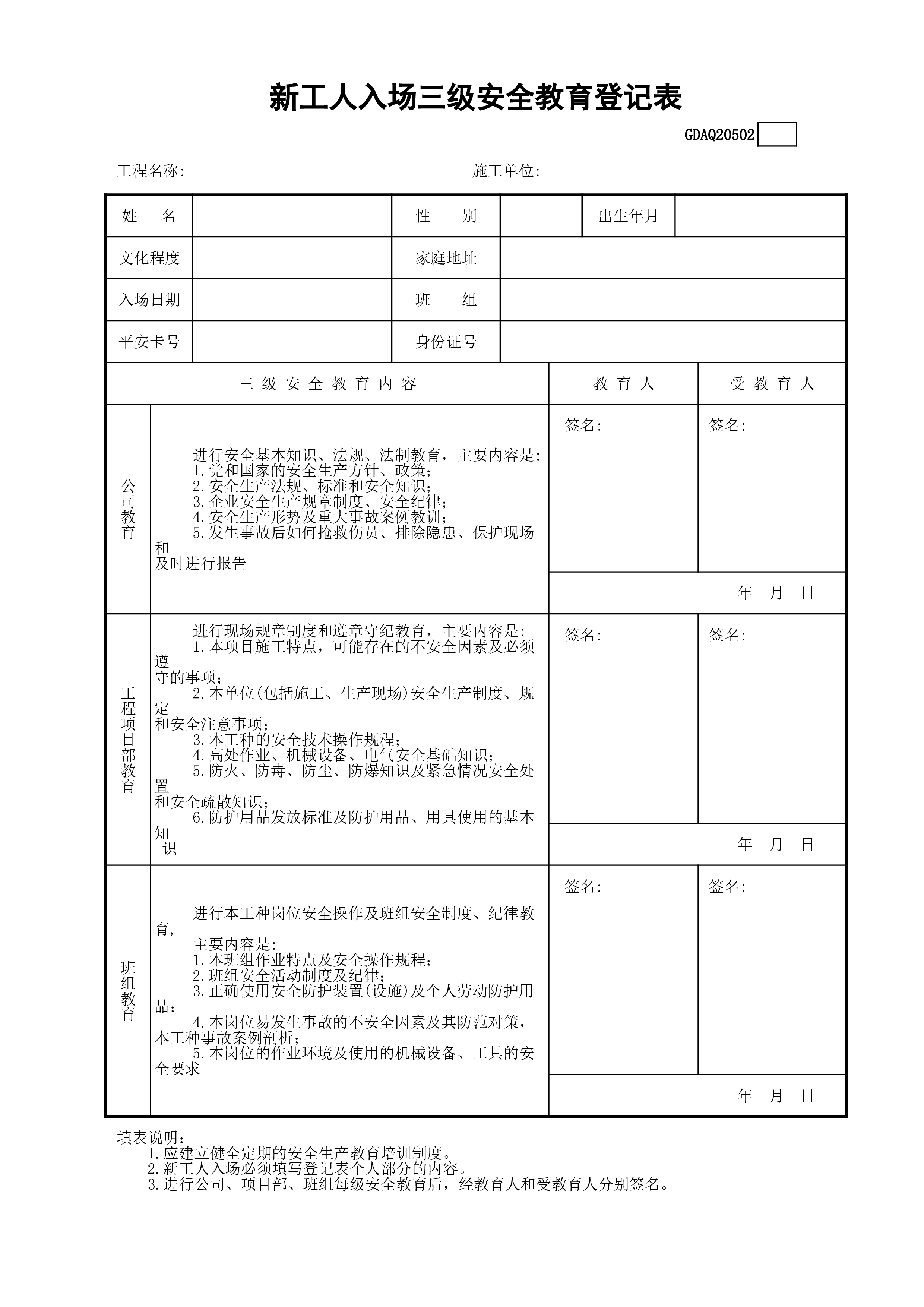

新工人入场三级安全教育登记表GDAQ20502VIP免费

2024-09-29 2

2024-09-29 2 -

【制度】防洪防汛安全管理制度(13页)VIP免费

2024-10-04 2

2024-10-04 2 -

企业级活动客户投诉处理预案

2024-10-08 13

2024-10-08 13 -

三农公共服务建设方案

2024-10-16 8

2024-10-16 8

分类:行业资料

价格:1库币

属性:108 页

大小:754.99KB

格式:PDF

时间:2024-06-16